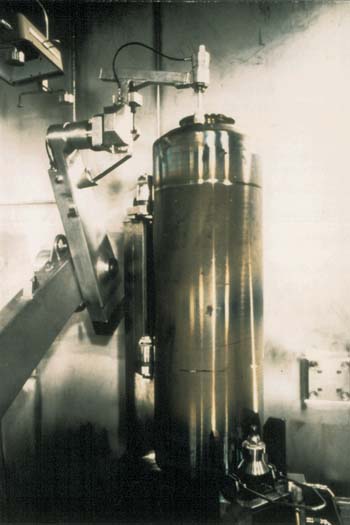

Technical complements: What is a canister of HLW?Borosilicate glass performances To safely dispose of the fission products and the long-lived actinides removed from the spent fuel, it is necessary to secure them in a matrix which has characteristics suitable for final disposal, especially stability and good leach resistance. After extensive research in several countries, glass has proven to be the optimal solution for immobilising the more than 30 different chemical elements present in the highly radioactive liquid waste solution. Nature provides examples of the glass obsidian for example remaining for thousands of years without alteration. There is an international consensus (France, Japan, UK, USA, Germany...) on the choice of borosilicate glass as being the best matrix for immobilising fission products and long-lived actinides in a solid form. In France, studies on this type of glass began in the 1960's. The R & D activities aimed at finding the most appropriate glass formulations by studying the behaviour of selected formulations and developing the industrial technology. A first active facility was commissioned in 1978 in Marcoule (AVM). The operating experience gained with AVM was a valuable input to the design of two further units, which started active operation in 1989 (R7) and 1992 (T7) at La Hague. In Japan, similar glass formulations have been studied for a long time and the pilot Tokai Vitrification Facility (TVF) started operating in April 1996. HLW canister during final control step |